Acid Yellow Dyes

Price 01 INR/ Kilograms

Acid Yellow Dyes Specification

- Rubbing Resistance

- Moderate

- Boiling point

- Decomposes

- Molecular Formula

- C16H11N2NaO4S (example for Acid Yellow 36)

- Shape

- Solid

- Resistance

- Good light and wash fastness

- Melting Point

- 205-210C

- Water Resistance

- Excellent

- Size

- Custom Packaging

- Purity

- 98% Min

- Other Names

- Acid Yellow 36, Acid Yellow 23, Tartrazine (depending on variant)

- Density

- 1.52 Gram per cubic centimeter(g/cm3)

- Strength

- 200% (variable, standardised strength)

- Structural Formula

- As per respective Acid Yellow Dye

- HS Code

- 3204

- Application

- Wool, Silk, Nylon, Paper, Ink, Cosmetics

- Moisture (%)

- <1.0%

- Poisonous

- Non-poisonous under normal usage

- Solvent Color

- Bright Yellow

- Shelf Life

- 24 Months

- Taste

- Odorless

- Grade

- Industrial Grade

- Ph Level

- 4-6 (acidic)

- Solubility

- Soluble in Water

- Smell

- Slight characteristic odor

- CAS No

- Various (commonly 135-49-9 or 2834-97-5 depending on exact dye type)

- Type

- Acid Dye

- Usage

- Textile, Paper, Leather, Cosmetic, and Ink Industries

- EINECS No

- 215-736-8 (example for Acid Yellow 36)

- Physical Form

- Powder or Granules

Acid Yellow Dyes Trade Information

- Minimum Order Quantity

- 01 Kilograms

- Supply Ability

- 1000 Kilograms Per Day

- Delivery Time

- 1-2 Days

- Sample Available

- Yes

- Main Export Market(s)

- Asia, Australia, North America, South America, Eastern Europe, Middle East, Africa, Central America, Western Europe

- Main Domestic Market

- All India

About Acid Yellow Dyes

| On Cotton | C.I. Product Name | Product Name |

| Acid Yellow 3 | Quinoline Yellow 3GX | |

| Acid Yellow 17 | Light Yellow 2GX | |

| Acid Yellow 34 | Yellow 3GL | |

| Acid Yellow 42 | Milling Fast Yellow MR | |

| Acid Yellow 49 | Yellow FGX | |

| Acid Yellow 99 | Yellow GR | |

| Acid Yellow 194 | Yellow M3RL | |

| Acid Yellow 204 | Yellow M5RL | |

| Acid Yellow 151 | Yellow NWX | |

| Acid Yellow 110 | Yellow 5GN | |

| Acid Yellow 186 | Yellow PGR | |

| Acid Yellow 199 | Yellow A4R |

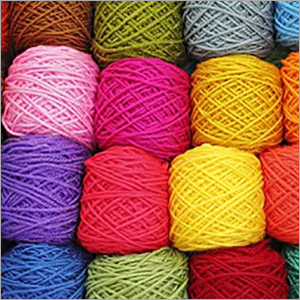

Superior Staining Strength for Multiple Industries

Acid Yellow Dyes offer a high staining strength, ensuring vivid and consistent coloration across textiles, papers, leathers, cosmetics, and inks. Their compatibility with various substrates such as wool, silk, nylon, and paper makes them a trusted choice among manufacturers aiming for superior quality and reliable results.

Optimized for Industrial Handling and Storage

Packaged in robust 25kg/50kg HDPE bags, cartons, or drums, these dyes maintain integrity during transport and storage. With a shelf life of 24 months, storing them in cool, dry, sun-protected places helps preserve their purity and effectiveness for long-term use in large-scale operations.

Environmental Safety and Regulatory Compliance

Acid Yellow Dyes comply with international environmental and safety standards, exhibiting low impact under regular handling. Their heavy metal content is well below safety thresholds (<20ppm), providing assurance for safe industrial application and export.

FAQs of Acid Yellow Dyes:

Q: How should Acid Yellow Dyes be stored to maintain their quality?

A: Acid Yellow Dyes must be stored in a cool, dry place away from sunlight. Proper storage in HDPE bags, cartons, or drums ensures their effectiveness and full shelf life of 24 months.Q: What is the main application process for Acid Yellow Dyes in industries?

A: These dyes are used primarily for dyeing wool, silk, nylon, paper, ink, and cosmetics. The process involves dissolving the dye in water and applying it through immersion or printing, owing to its solubility and high staining strength.Q: What are the benefits of using Acid Yellow Dyes for industrial coloring?

A: Acid Yellow Dyes provide bright yellow shades with excellent solubility, high staining strength, good heat and wash fastness, and environmental compliance, ensuring vivid and durable results suitable for a variety of industrial applications.Q: When is it recommended to use Acid Yellow Dyes over other dye types?

A: These dyes are recommended when bright yellow coloration, high compatibility, and strong staining are required, especially for acid-compatible fibers such as wool, silk, and nylon, or when environmental compliance is essential.Q: Where are Acid Yellow Dyes commonly used?

A: They are extensively employed in the textile, paper, leather, cosmetic, and ink industries. Their versatility makes them suitable for manufacturing in India and exporting worldwide.Q: How do Acid Yellow Dyes comply with safety standards?

A: They contain less than 20 ppm heavy metals, comply with major international environmental norms, and are non-poisonous under standard usage, making them safe for manufacturing and application.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Acid Dyes Category

Acid Violet Dyes

Price 01 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Usage : Other, Textile Dyeing

Solubility : Soluble in water

Smell : Other, Odorless

CAS No : None (Acid Violet Dyes are typically mixtures, not single compounds)

Acid Green Dyes

Minimum Order Quantity : 100 Kilograms

Usage : Paper Dyestuffs

Solubility : Soluble in water

Smell : Other, Odorless

CAS No : 10241211

Acid Brown Dyes

Price 01 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Usage : Other, Textile dyeing, coloring leather, paper, and indicators

Solubility : Soluble in water

Smell : Other, Odorless

CAS No : Variable depending on specific dye (typically in the range of 5858373 to 6416979 for common Acid Brown variants)

Acid Dyes

Price 01 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Usage : Textile Dyestuffs, Other

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS